Reconstruction of Wacker Drive Viaduct with Post-Tensioning System

The Wacker Drive Viaduct is under a 2-years major reconstruction effort to accommodate the estimated average daily traffic of nearly 32,000 to 39,000 vehicles.

Context

The Viaduct is a 2-level, 4 to 8-lane urban viaduct along the Chicago River in the heart of Chicago’s financial district. The project also incorporates the City’s river walk, accommodating 60,000 pedestrians per day.

The site is bounded by the Chicago River along one full side, city skyscrapers, and several bascule bridges to be restored and crossed by two elevated rail transit lines. Construction at 10 separate cross-street intersections is coordinated to minimize disruption to the approximately 125,000 vehicles per day that cross Wacker Drive.

Solution

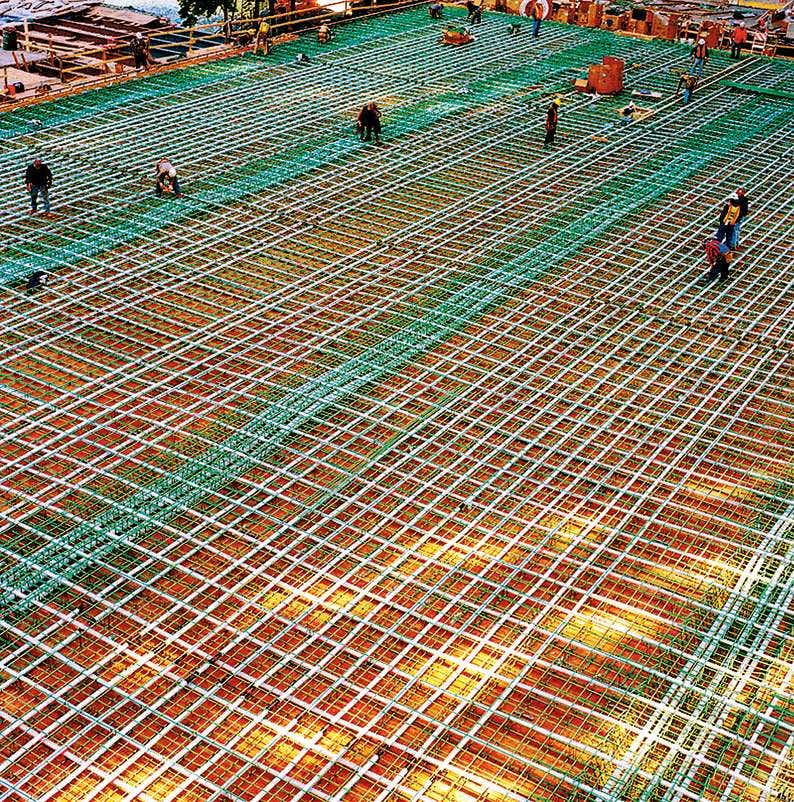

A cast-in-place post tensioned concrete design was chosen to provide an accelerated construction schedule and to keep the superstructure section as shallow as possible or overhead clearance on the lower level. Split into three separate contracts, total post-tensioning materials weigh in excess of 1,220 t.

Almost 1 million linear meters of 0.6" prestressing strand was required to complete all three phases. Tendon sizes used are the 4-0.6" flat system for transverse tendons and 5, 9 and 12-0.6" MA system for longitudinal tendons. To help insure durability, all tendons on this project were required to use plastic ducts.

The difficult access to the project complicated the intensive construction schedule and staging of materials and activities. To assist DYWIDAG prefabricated all tendons in its North Central Division warehouse facility located in Bolingbrook, IL, just outside Chicago and delivered them to the project site ready for installation into the structure.